the group’s subsidiary Atlantec in France took delivery and installation of the brand new A9 system from atg Luther & Maelzer through its distributor ADEON Technologies. The Group ACB has a long-term experience with the Flying Probe Electrical test systems from atg-LM for it’s PCB production.

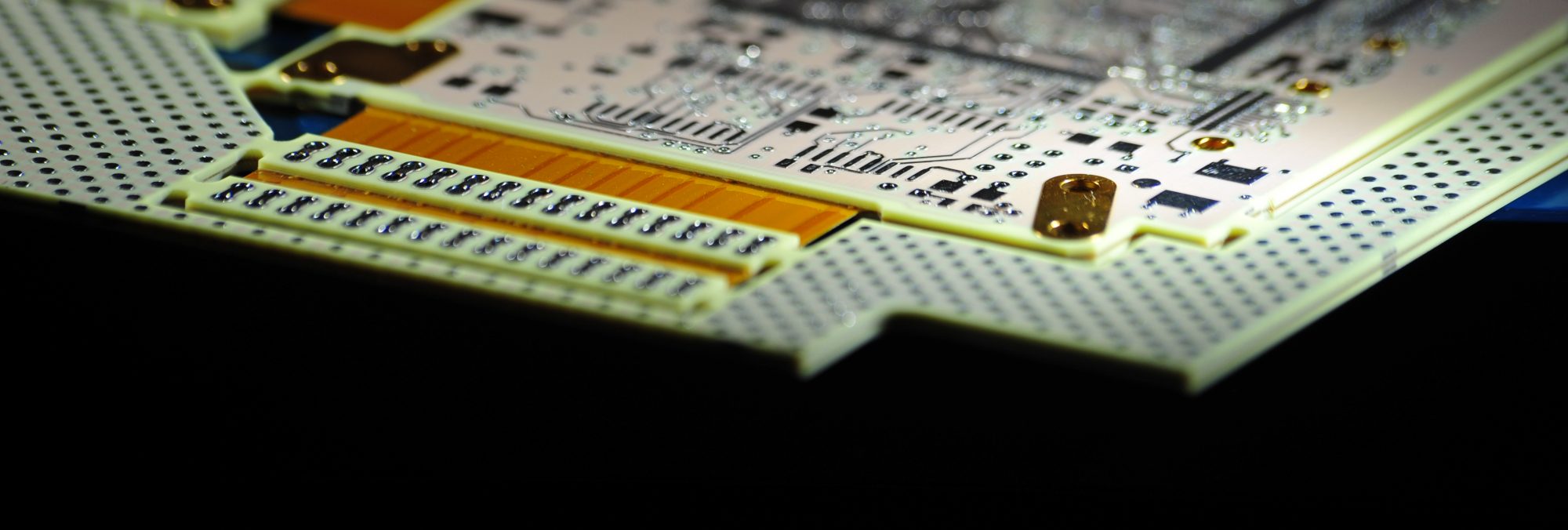

There is a clear increase of complexity throughout the range of printed circuits that are required by the end users. The demand for higher volume, as well as higher mix of products prescribe the need for reliable electrical test systems to secure the 100% functionality of the products. Additional fact is that the number of circuits, and as a result the amount of testpoints, are increasing per design and the features to be tested are getting smaller all the time.

It was therefore a rather obvious decision to purchase the state-of-the-art A9 system from atg-LM. The company are the world leaders in electrical testing of printed circuits with a proven track record. Besides the price to performance ratio, atg-LM delivers reliability, robustness, speed, accuracy, and first-class service through its distribution partner. The A9 systems are fully compatible with the other systems in use at the Group ACB , but the speed and accuracy of the new system is unrivalled.